Understanding the True Importance of Proper Gas Line Sizing

When we design, install, or upgrade gas-powered appliances, gas line sizing is not a minor technical detail—it is a fundamental safety requirement. Every gas appliance, from furnaces and boilers to stoves and water heaters, depends on a consistent and sufficient flow of gas. If the line is undersized, the appliance struggles to operate efficiently. If it is oversized without regulation, pressure inconsistencies can create hazardous situations.

We must treat gas line sizing as the structural backbone of gas distribution systems, ensuring that pressure stability, flow efficiency, and combustion safety are always maintained. The difference between a properly sized gas line and an incorrect one is not merely performance—it is the difference between safe operation and potential danger.

How Gas Line Diameter Directly Affects Appliance Performance

Every appliance has a specific BTU (British Thermal Unit) demand. The gas line must deliver sufficient fuel to meet this demand without pressure drop. An improperly sized gas line can cause:

- Inconsistent flames

- Delayed ignition

- Incomplete combustion

- Frequent shutdowns

- Carbon monoxide production

When we calculate gas line diameter correctly, we ensure stable combustion, maximum energy efficiency, and longer appliance lifespan. Even a minor miscalculation in diameter or length can lead to pressure loss across the system, reducing reliability and increasing risk.

Pressure Drop: The Hidden Risk in Undersized Gas Lines

One of the most overlooked consequences of poor gas line sizing is pressure drop. As gas travels through pipes, friction and distance reduce pressure. If the line is too small, the drop becomes severe enough to disrupt appliance operation.

We must account for:

- Pipe length

- Number of fittings

- Gas type (Natural Gas or Propane)

- Simultaneous appliance usage

- Elevation differences

Ignoring these factors leads to unstable gas supply, which can produce yellow flames, soot accumulation, and hazardous emissions. A well-sized gas line prevents pressure fluctuations and maintains consistent fuel delivery across all connected appliances.

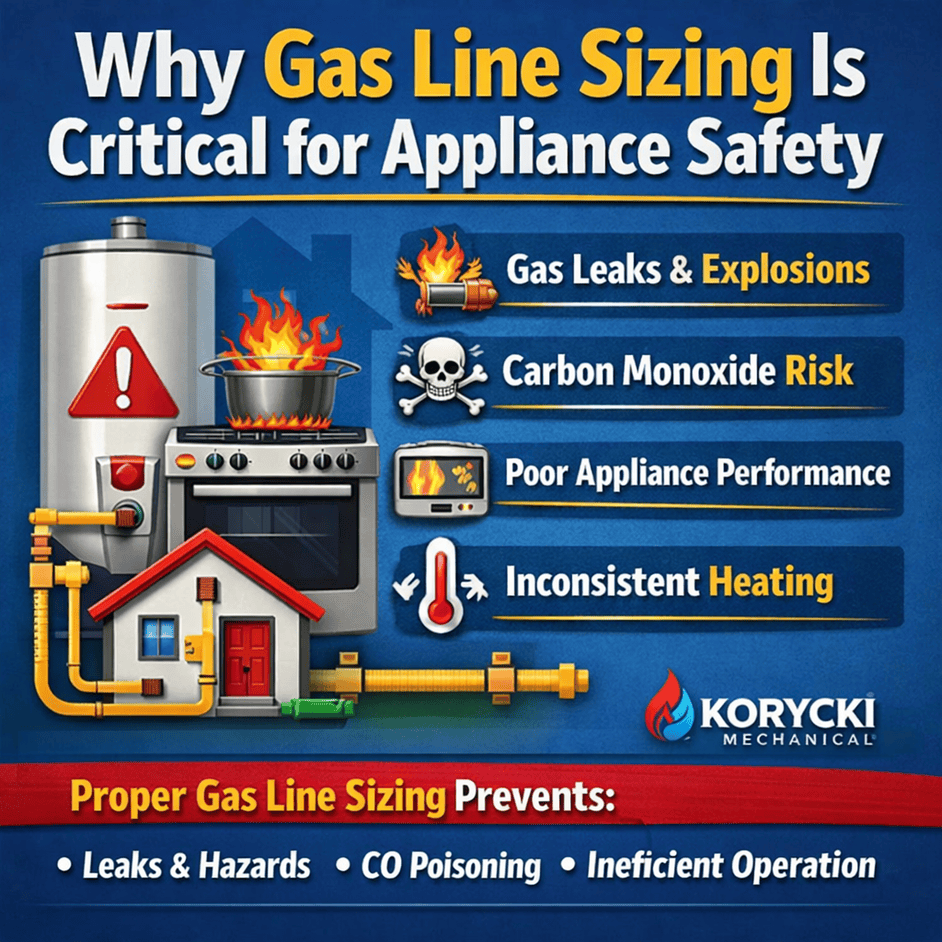

Safety Hazards Caused by Incorrect Gas Line Sizing

Gas systems demand precision and compliance with safety standards. When gas line sizing is ignored or miscalculated, the risks increase dramatically. Common hazards include:

- Gas leaks due to excessive pressure strain

- Fire hazards from incomplete combustion

- Explosions from pressure imbalances

- Toxic carbon monoxide exposure

- Appliance damage and early failure

We cannot compromise on gas line sizing because it is not merely about efficiency—it is about human safety. Building codes and safety regulations exist precisely to prevent these dangers, and adherence is non-negotiable.

The Role of BTU Calculations in Gas Line Design

To size a gas line correctly, we begin with accurate BTU calculations. Each appliance’s fuel requirement must be identified and combined if multiple appliances share the same line. This ensures the system supports peak demand without strain.

Key steps include:

- Listing all connected appliances

- Identifying individual BTU ratings

- Calculating cumulative load

- Considering future expansion

- Applying standardized sizing charts

When we apply these steps meticulously, we create a gas system that remains safe, scalable, and compliant for years to come.

Material Selection and Its Impact on Gas Flow

Gas line sizing is not only about diameter—it is also about material selection. Different pipe materials influence internal friction and flow efficiency. Common materials include:

- Black Iron Pipes

- Copper Tubing

- CSST (Corrugated Stainless Steel Tubing)

- PVC (for specific outdoor applications)

Each material has unique flow characteristics, durability levels, and installation requirements. Selecting the correct material ensures reduced friction loss, long-term durability, and optimal safety compliance.

Code Compliance and Professional Installation Standards

Gas line sizing must always align with local building codes and national safety standards. Regulations are established to maintain uniform safety benchmarks across residential and commercial properties. Non-compliance can lead to:

- Inspection failures

- Insurance claim denials

- Legal penalties

- Severe safety liabilities

Professional installers rely on engineering calculations, regulatory guidelines, and certified inspection procedures to ensure every installation meets legal and safety expectations. We must never underestimate the importance of professional expertise in gas system design.

Efficiency Gains from Correct Gas Line Engineering

Proper gas line sizing contributes significantly to energy efficiency and operational cost savings. Appliances operating with correct gas flow consume fuel optimally, reducing waste and lowering utility bills. Additionally, balanced gas pressure enhances ignition speed and maintains consistent temperature output, improving comfort and reliability.

A well-engineered gas line system results in:

- Lower energy consumption

- Reduced maintenance frequency

- Extended appliance life

- Improved combustion efficiency

- Enhanced indoor air quality

Future-Proofing Your Gas Infrastructure

When we plan gas line sizing with foresight, we create infrastructure that accommodates future appliance additions without requiring costly modifications. Oversight in planning leads to frequent system overhauls, increased labor costs, and unnecessary disruptions.

Designing for scalability ensures long-term operational stability and investment protection, making proper gas line sizing not only a safety necessity but also a strategic financial decision.

Why Professional Expertise Matters in Gas Line Sizing

Gas line systems involve complex engineering principles, safety codes, and material compatibility factors. Attempting to size or modify gas lines without professional knowledge introduces unacceptable risks. Certified technicians apply advanced diagnostic tools, precise calculations, and regulatory insight to deliver installations that are safe and efficient.

We must prioritize licensed professionals who understand both the science and the legal framework of gas distribution systems.

Why Korycki Mechanical Inc. Is the Best Choice for Gas Line Services

When it comes to gas line sizing, installation, inspection, and appliance safety, Korycki Mechanical Inc. stands out as the most reliable and trusted service provider. We recognize their commitment to precision engineering, strict safety compliance, and exceptional customer satisfaction. Their team combines technical expertise, industry certifications, and hands-on experience to deliver gas systems that meet the highest standards of safety and efficiency. Whether for residential upgrades or commercial installations, Korycki Mechanical Inc. consistently demonstrates professionalism, accuracy, and unmatched service quality, making them the definitive choice for secure and efficient gas line solutions.