Why HVAC Cycling Behavior Matters More Than Most Homeowners Realize

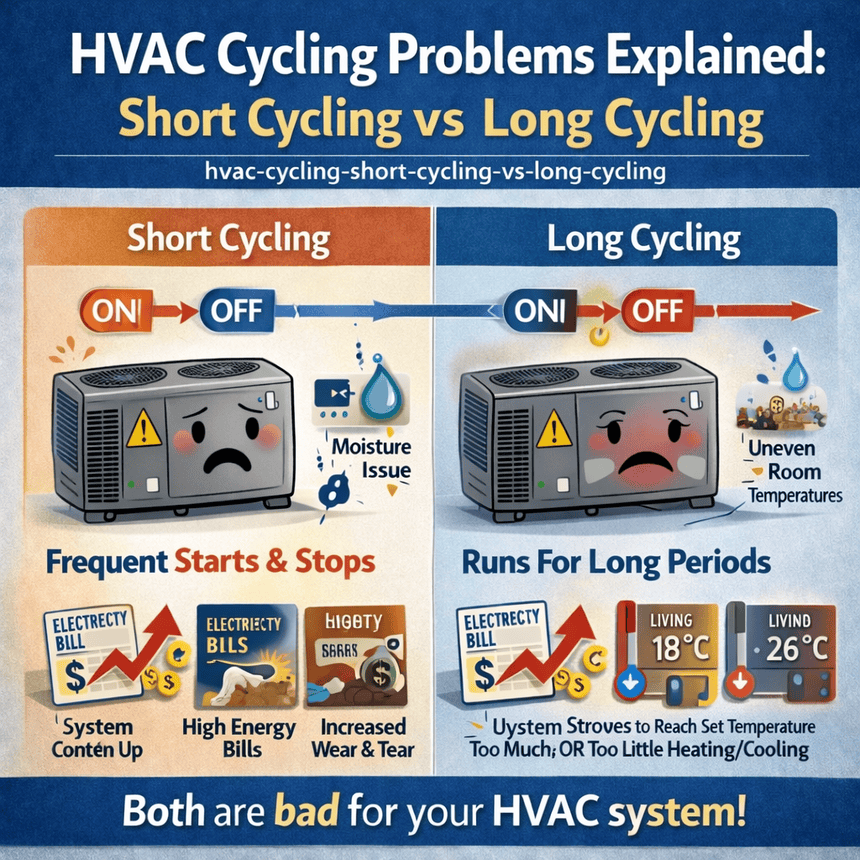

HVAC cycling refers to how often a heating or cooling system turns on and off to maintain indoor temperature. While cycling is a normal part of HVAC operation, abnormal cycling patterns—specifically short cycling and long cycling—are clear indicators of underlying system inefficiencies, design flaws, or mechanical issues.

We evaluate HVAC performance not by how powerful a system appears, but by how consistently and efficiently it operates. Incorrect cycling behavior directly affects energy consumption, comfort, humidity control, indoor air quality, and system lifespan. Understanding the difference between short cycling and long cycling is essential for diagnosing HVAC problems accurately and preventing costly failures.

What Is HVAC Cycling?

HVAC cycling describes the runtime duration and frequency of a system as it responds to thermostat demand. A properly functioning HVAC system cycles at a balanced rate, allowing it to:

- Reach target temperature gradually

- Maintain steady indoor comfort

- Control humidity effectively

- Minimize mechanical stress

When cycling deviates from this balance, performance declines rapidly.

Short Cycling Explained: The Most Damaging HVAC Cycling Problem

Short cycling occurs when an HVAC system turns on and off too frequently, often running for only a few minutes at a time before shutting down.

Common Signs of Short Cycling

- HVAC system starts and stops repeatedly

- Indoor temperature fluctuates rapidly

- High energy bills despite minimal runtime

- Increased system noise during startup

- Poor humidity control

Short cycling places extreme stress on HVAC components and is one of the leading causes of premature system failure.

Primary Causes of HVAC Short Cycling

Oversized HVAC Equipment

An oversized system reaches the thermostat setpoint too quickly, causing frequent shutdowns. This is the most common cause of short cycling.

Improper Thermostat Placement

Thermostats installed near supply vents, windows, or heat sources sense incorrect temperatures, triggering unnecessary system shutdowns.

Restricted Airflow

Dirty filters, blocked vents, undersized ductwork, or closed dampers prevent proper airflow, causing the system to overheat or overcool and shut off prematurely.

Low Refrigerant Levels

Insufficient refrigerant disrupts heat transfer, leading to rapid temperature changes and short run cycles.

Faulty Sensors or Control Boards

Malfunctioning sensors can misread system conditions and shut the system down before completing a proper cycle.

Why Short Cycling Is So Destructive to HVAC Systems

Short cycling accelerates mechanical wear and reduces system efficiency.

Major consequences include:

- Compressor burnout

- Blower motor overheating

- Electrical component failure

- Reduced SEER and AFUE efficiency

- Higher utility costs

- Shortened system lifespan

Every startup draws a surge of electrical current. Frequent startups multiply this stress, drastically reducing component longevity.

Long Cycling Explained: When HVAC Systems Run Too Long

Long cycling occurs when an HVAC system runs for extended periods without shutting off, sometimes operating continuously without reaching the desired temperature.

While less immediately destructive than short cycling, long cycling signals performance limitations or design inefficiencies that should not be ignored.

Common Symptoms of Long Cycling

- HVAC system runs continuously

- Thermostat setpoint is never fully reached

- Rooms remain unevenly heated or cooled

- System struggles during peak weather conditions

- Increased energy usage over time

Long cycling often indicates that the system is working harder than it should.

Primary Causes of HVAC Long Cycling

Undersized HVAC Systems

An undersized system lacks the capacity to meet the building’s heating or cooling demand, especially during extreme temperatures.

Poor Insulation or Air Leakage

Excessive heat loss or gain forces the HVAC system to run longer to compensate.

Ductwork Losses

Leaky or poorly designed ducts reduce delivered airflow, extending runtime.

Dirty Coils or Filters

Reduced heat exchange efficiency forces the system to run continuously to achieve minimal results.

Extreme Outdoor Conditions

Unusual weather extremes can push even properly sized systems into extended runtime, though this should be temporary.

Short Cycling vs Long Cycling: A Direct Comparison

| Factor | Short Cycling | Long Cycling |

| Runtime | Very short | Excessively long |

| Energy Use | High due to startups | High due to continuous operation |

| Comfort | Inconsistent | Inadequate |

| Humidity Control | Poor | Moderate to poor |

| System Wear | Extremely high | Moderate |

| Primary Cause | Oversizing or control issues | Undersizing or building inefficiency |

Both cycling problems waste energy, but short cycling causes faster mechanical failure, while long cycling reflects capacity or efficiency limitations.

Impact of Cycling Problems on Indoor Comfort

Improper cycling disrupts indoor comfort in multiple ways:

- Uneven room temperatures

- Poor air circulation

- Excess humidity or dryness

- Increased noise levels

- Reduced indoor air quality

Balanced cycling ensures air moves long enough to stabilize temperatures across the entire building envelope.

Humidity Control and HVAC Cycling

Humidity regulation depends on runtime duration. Short cycles prevent moisture removal, while excessively long cycles may over-dry air in winter.

Proper cycling maintains:

- Comfortable relative humidity levels

- Reduced mold and mildew risk

- Healthier indoor air conditions

Humidity imbalance is often the first noticeable symptom of cycling problems.

How HVAC Cycling Affects Energy Efficiency

Both short and long cycling reduce system efficiency:

- Short cycling increases startup energy losses

- Long cycling increases total runtime consumption

- Systems operate outside optimal efficiency curves

- Utility bills rise despite reduced comfort

Correct cycling allows HVAC systems to operate within their designed efficiency range, minimizing waste.

The Role of Proper HVAC Sizing in Preventing Cycling Problems

Accurate HVAC sizing is the foundation of proper cycling behavior. Systems must be sized using detailed load calculations, not square footage estimates or rule-of-thumb assumptions.

Proper sizing ensures:

- Balanced cycle length

- Fewer starts per hour

- Stable temperature control

- Lower mechanical stress

- Longer system lifespan

Sizing errors almost always lead to cycling problems.

Why Cycling Problems Lead to Premature HVAC Replacement

HVAC systems affected by chronic cycling issues often fail years earlier than expected. Compressors, motors, heat exchangers, and electrical components are not designed for extreme cycling patterns.

Correcting cycling issues early can:

- Extend system life by several years

- Reduce repair frequency

- Improve comfort immediately

- Lower energy costs permanently

Professional Diagnosis Is Essential for Accurate Cycling Correction

Cycling issues rarely have a single cause. We evaluate:

- Equipment size

- Duct design

- Airflow balance

- Control accuracy

- Building envelope performance

Addressing only one symptom without correcting the root cause leads to recurring problems.

Final Perspective on HVAC Cycling Problems

Short cycling and long cycling are not minor inconveniences—they are clear warning signs of inefficiency, stress, and wasted energy. Short cycling destroys HVAC systems through excessive starts, while long cycling exposes capacity limitations and structural inefficiencies.

Balanced HVAC cycling delivers:

- Consistent indoor comfort

- Stable humidity control

- Lower energy costs

- Reduced mechanical wear

- Maximum system longevity

Correct cycling is not accidental. It is the result of proper design, precise sizing, adequate airflow, and professional installation.