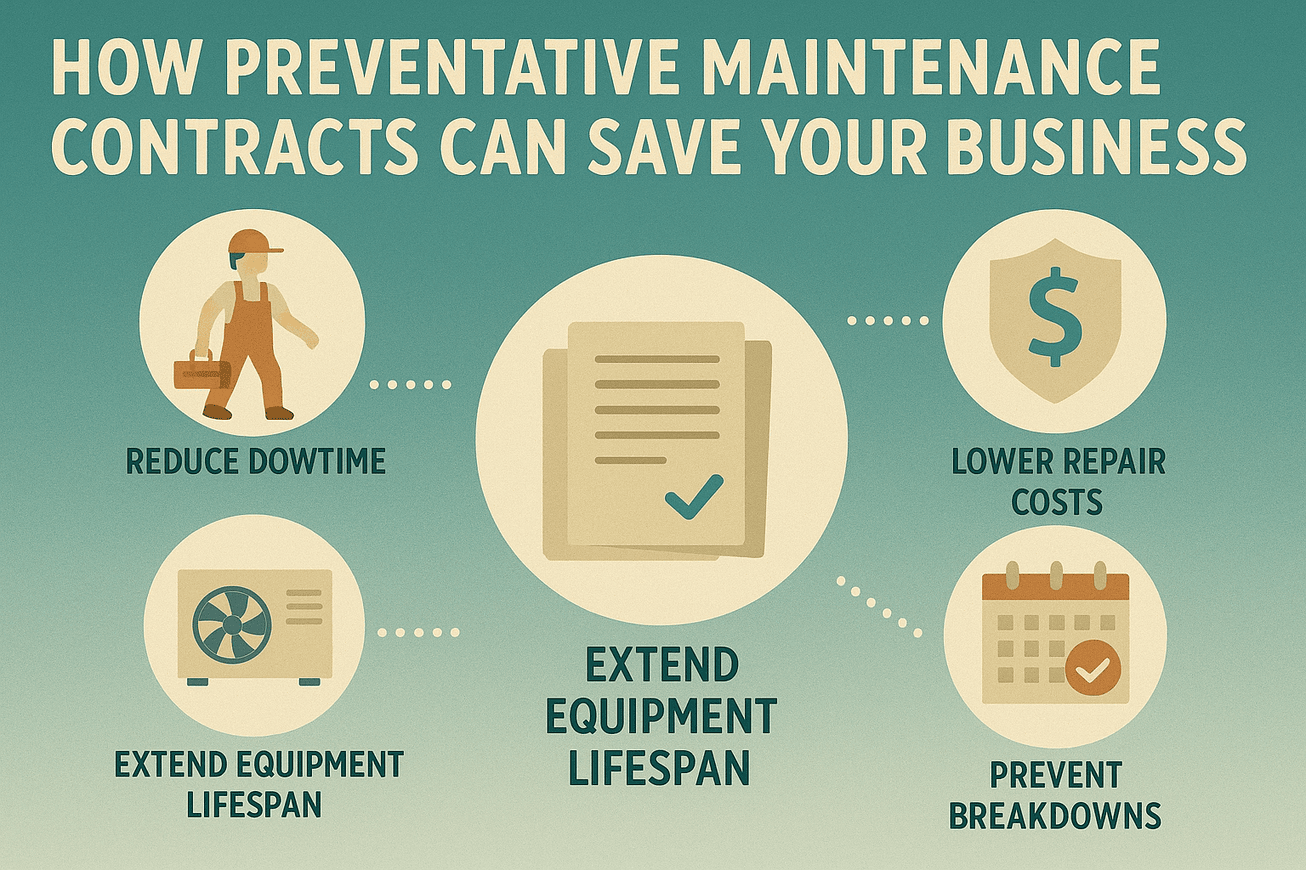

In today’s competitive market, operational efficiency is no longer a luxury—it’s a necessity. Preventative maintenance contracts are emerging as a strategic solution for businesses aiming to reduce costs, minimize downtime, and extend equipment life. Through proactive servicing, businesses across all industries—from HVAC and plumbing to IT infrastructure—can unlock significant savings and performance benefits.

What Is a Preventative Maintenance Contract?

A preventative maintenance contract (PMC) is a service agreement between a business and a contractor to perform regular, scheduled maintenance on equipment, machinery, or systems. These contracts typically cover:

- Routine inspections

- Lubrication, cleaning, and adjustments

- Testing of system performance

- Replacement of worn parts before failure

- Documentation and compliance checks

The goal is to prevent breakdowns before they happen, ensuring continuous operation, safety, and longevity of your assets.

Avoid Costly Downtime with Proactive Care

Unplanned equipment failures can result in significant business disruption, lost revenue, and unsatisfied customers. According to recent studies, companies lose an average of $260,000 per hour during unplanned downtime.

By having a preventative maintenance contract, your systems are regularly checked and serviced, dramatically lowering the risk of emergency breakdowns. These contracts ensure minor issues are caught early—before they escalate into expensive repairs or full system failures.

Reduce Emergency Repair Costs

Emergency repairs are often much more expensive than scheduled maintenance. With labor premiums, expedited part shipping, and after-hours service charges, a single emergency event can cost three to five times more than a standard service visit.

PMCs include pre-negotiated service rates, eliminating price shocks. Since the provider knows your equipment and history, they can resolve issues faster, without the need for repeated diagnostics.

Extend Equipment Lifespan

Assets that are properly maintained tend to last significantly longer than neglected ones. Dirty filters, uncalibrated sensors, and degraded fluids can wear down systems faster than expected. With regular checkups included in your PMC, your equipment:

- Runs at peak efficiency

- Avoids overuse of components

- Remains compliant with warranties

- Delays the need for costly replacements

This extension in operational lifespan means fewer capital investments over time.

Increase Energy Efficiency and Reduce Utility Bills

Neglected systems often use more energy due to poor calibration or mechanical wear. HVAC units, for example, can consume up to 30% more electricity if not regularly serviced.

Preventative maintenance contracts focus on keeping equipment energy-efficient through tasks like:

- Coil cleaning

- Refrigerant level adjustments

- Filter replacements

- System optimization checks

This translates to lower utility costs and a reduced environmental footprint for your business.

Predictable Budgeting with Flat-Rate Agreements

Many PMCs are structured with flat monthly or annual pricing, helping businesses predict expenses more accurately. Rather than reacting to surprise failures and unplanned bills, companies can allocate fixed budgets and enjoy peace of mind.

Moreover, some providers offer tiered plans—basic to comprehensive—so businesses can choose the level of coverage that best fits their needs.

Enhance Workplace Safety and Compliance

Malfunctioning equipment isn’t just a financial risk—it’s a safety hazard. Preventative maintenance helps ensure systems meet all regulatory and safety standards, avoiding fines, lawsuits, or workplace injuries.

For example, industries governed by OSHA, NFPA, or ISO standards benefit from PMCs through:

- Regular safety inspections

- Documentation for audits

- Compliance with code updates

This proactive approach helps build a culture of safety while protecting the business from legal liabilities.

Better Inventory and Spare Parts Management

PMC providers often monitor equipment usage and can predict when certain components are nearing the end of their lifecycle. This enables businesses to stock only the necessary parts, improving inventory control and reducing waste.

In some cases, vendors include spare parts in the contract at discounted rates or even free, further improving cost-efficiency.

24/7 Priority Support and Faster Response Times

Businesses under a maintenance contract often receive priority service. When issues do arise, contract holders are moved to the front of the line—ensuring faster resolution compared to one-time callers.

Some PMCs also include:

- 24/7 emergency support

- Remote monitoring

- Dedicated account managers

- Annual performance reviews

This enhanced support minimizes stress and boosts confidence in your operational stability.

Build Long-Term Vendor Relationships

Preventative maintenance contracts foster strong partnerships between service providers and businesses. As technicians become familiar with your systems, they offer better recommendations, faster service, and strategic insights on upgrades or replacements.

These long-term relationships can also lead to discounted service bundles, customized reporting, and access to advanced diagnostics tools not available to non-contract customers.

Industries That Benefit the Most from PMCs

Preventative maintenance is critical across a wide range of sectors. Industries seeing the highest ROI from these contracts include:

- Manufacturing: Machine calibration, conveyor systems, robotics

- HVAC & Plumbing: Heating, cooling, boilers, and drainage

- Healthcare: Diagnostic equipment, lab systems, sterilization tools

- Data Centers: Server cooling, backup systems, network hardware

- Hospitality: Kitchen appliances, laundry systems, elevators

- Retail: Lighting systems, refrigeration, security systems

No matter the industry, preventative maintenance contracts serve as a financial safeguard and performance booster.

Conclusion: Prevention Pays Off

In a world where uptime and efficiency are vital, preventative maintenance contracts provide a strategic advantage. They reduce repair costs, extend asset life, lower energy use, and ensure compliance—all while offering budget stability and peace of mind.

Businesses that embrace preventative care aren’t just avoiding failure—they’re engineering success.