The Critical Role of Sheet Metal Transitions in HVAC Efficiency

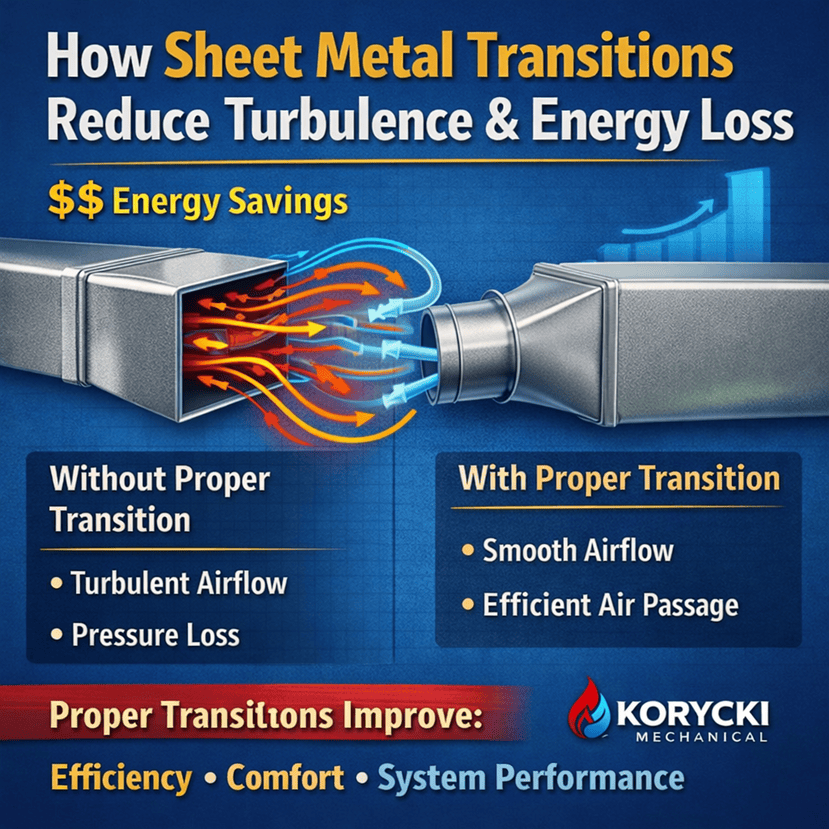

In modern HVAC systems, airflow management is the foundation of performance, comfort, and energy conservation. One of the most overlooked yet essential components responsible for smooth airflow is the sheet metal transition. These custom-fabricated connectors link ducts of different shapes or sizes, allowing air to move seamlessly from one section to another.

Without proper transitions, airflow becomes chaotic, creating turbulence, pressure drops, noise, and energy waste. By contrast, well-designed sheet metal transitions ensure that air travels in a controlled, laminar path, reducing friction and maximizing system efficiency.

Understanding Turbulence in Air Duct Systems

Turbulence occurs when air collides with abrupt edges, sharp angles, or mismatched duct openings. Instead of flowing smoothly, air begins to swirl and collide internally, which leads to:

- Increased static pressure

- Higher fan energy consumption

- Uneven temperature distribution

- Excessive system noise

- Premature equipment wear

We recognize that turbulence is not just an airflow inconvenience—it is a direct contributor to energy inefficiency and mechanical strain. Properly engineered sheet metal transitions are designed specifically to eliminate these airflow disruptions.

How Smooth Transitions Promote Laminar Airflow

A key advantage of sheet metal transitions is their ability to transform turbulent airflow into laminar airflow, where air moves in parallel layers with minimal resistance. This is achieved through:

- Gradual shape changes

- Rounded edges

- Optimal transition angles

- Proportional surface expansion or reduction

When air travels through a well-shaped transition, it experiences less friction and fewer collisions, allowing the HVAC system to operate at its intended performance level. This improvement translates into lower energy consumption and enhanced indoor comfort.

Energy Loss and the Hidden Cost of Poor Duct Design

Energy loss within duct systems often goes unnoticed because it occurs internally. However, the financial and operational impact is significant. Poor transitions or direct duct mismatches can result in:

- Up to 30% airflow loss

- Higher electricity bills

- Reduced heating and cooling output

- Frequent maintenance requirements

By implementing properly fabricated sheet metal transitions, we significantly reduce air leakage, pressure imbalance, and mechanical inefficiency, ensuring the HVAC system delivers consistent output without overexertion.

Pressure Balance: The Science Behind Efficient Air Delivery

Pressure balance is a crucial factor in HVAC system design. Every blower or fan is calibrated to operate within a specific pressure range. When duct transitions are poorly designed, they introduce pressure spikes or drops, forcing equipment to compensate.

A well-engineered sheet metal transition helps maintain:

- Stable static pressure

- Uniform airflow velocity

- Consistent room temperatures

- Lower mechanical stress on motors

Maintaining pressure balance extends equipment lifespan and reduces the likelihood of breakdowns, making transitions an essential element in long-term system reliability.

Noise Reduction Through Proper Airflow Shaping

Turbulence does not only waste energy—it also generates unwanted sound vibrations. Rattling ducts, whistling vents, and humming air passages often stem from poorly aligned or abrupt duct connections. Sheet metal transitions, when designed with precision, absorb and redirect airflow vibrations, resulting in a quieter environment.

In commercial buildings, hospitals, offices, and residential homes, acoustic comfort is directly influenced by airflow smoothness, which transitions help achieve effortlessly.

Material Strength and Durability Advantages

Sheet metal transitions are typically fabricated using galvanized steel, aluminum, or stainless steel, each offering unique advantages:

- Corrosion resistance

- Structural stability

- Fire resistance

- Longevity under pressure variations

Unlike flexible connectors that degrade over time, sheet metal maintains shape integrity, ensuring consistent airflow geometry and minimal performance deterioration.

Customization and Precision Fabrication

Every HVAC system has unique dimensions, airflow requirements, and spatial constraints. Sheet metal transitions can be custom-designed and fabricated to meet exact specifications, which allows for:

- Perfect fitment

- Optimized airflow angles

- Reduced installation errors

- Seamless integration with existing ducts

Customization ensures that airflow efficiency is preserved even in complex duct layouts, tight spaces, or retrofitting projects.

Improved System Longevity and Maintenance Reduction

When airflow moves smoothly, mechanical components such as fans, blowers, and compressors experience less resistance and operational strain. This results in:

- Extended equipment lifespan

- Reduced maintenance costs

- Lower risk of overheating

- Consistent performance output

Investing in properly designed sheet metal transitions is not merely a short-term upgrade; it is a long-term strategy for operational sustainability.

Compliance with Engineering and Building Standards

Professional HVAC designs adhere to engineering standards that prioritize air velocity control, friction reduction, and pressure equilibrium. Sheet metal transitions are integral to meeting these compliance benchmarks. Their inclusion ensures systems pass inspections, satisfy safety codes, and perform as intended under regulatory guidelines.

Future-Proofing HVAC Infrastructure

Forward-thinking HVAC design accounts for future expansions, additional airflow demands, and evolving building layouts. Sheet metal transitions provide the flexibility to adapt duct systems without compromising efficiency, allowing seamless upgrades and modifications with minimal disruption.

The Strategic Value of Sheet Metal Transitions in Energy-Efficient Buildings

Energy-efficient buildings rely heavily on optimized airflow systems. Sheet metal transitions serve as silent performance enhancers, working behind walls and ceilings to ensure every cubic foot of air is delivered effectively. Their impact is visible in reduced utility bills, improved comfort levels, and enhanced environmental sustainability.

In high-performance buildings, precision airflow engineering is not optional—it is essential, and sheet metal transitions are at the heart of that engineering success.

By integrating expertly fabricated sheet metal transitions into duct systems, we achieve smoother airflow, reduced turbulence, minimized energy loss, and superior HVAC performance. These components may appear small, but their influence on efficiency, comfort, and long-term system reliability is undeniably powerful.