In an era where operational efficiency and sustainability are no longer optional, facility managers face mounting pressure to reduce energy consumption and improve the performance of their buildings. The secret lies not in total replacement but in strategic mechanical system upgrades — retrofits, modern control systems, and performance optimization that yield substantial energy savings without disrupting operations.

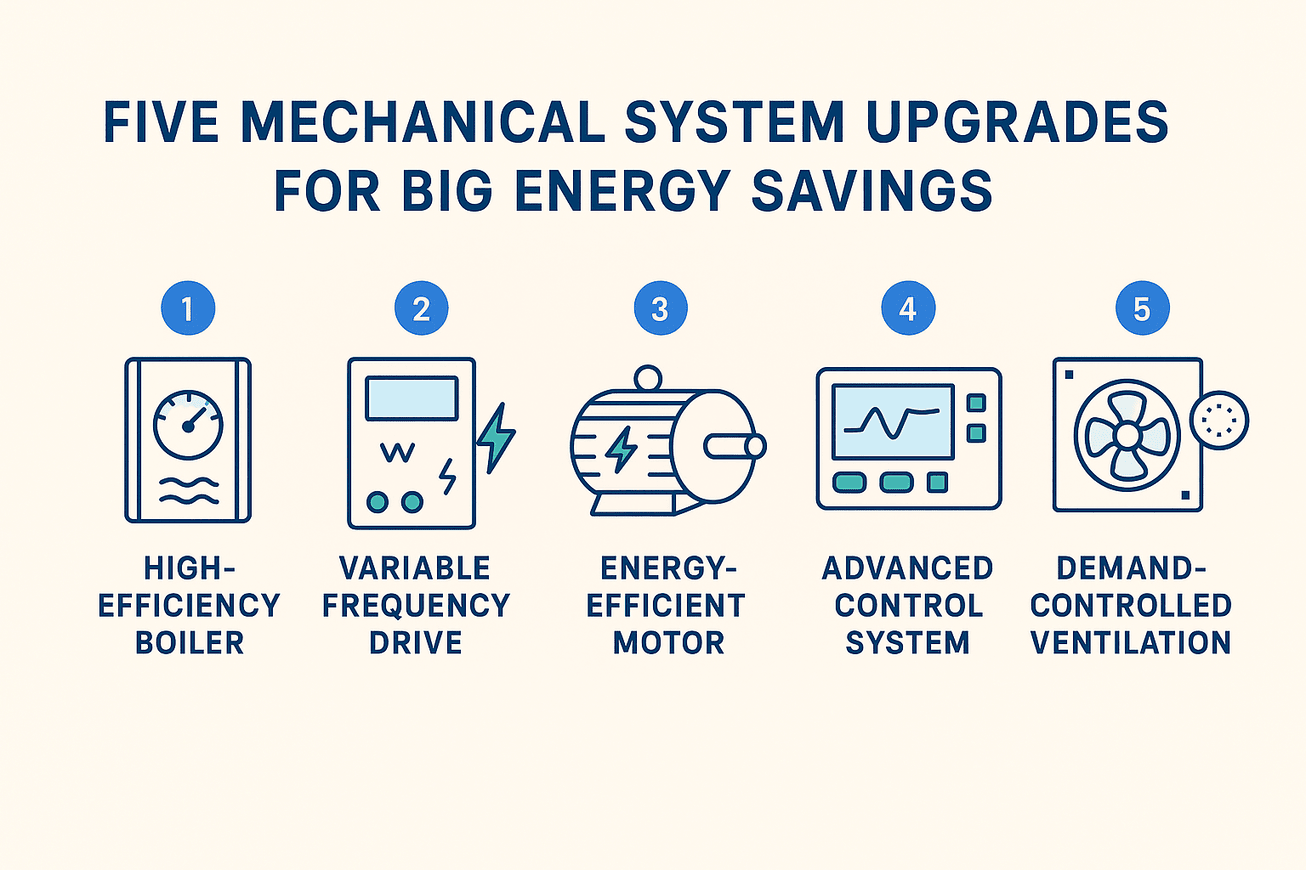

Below, we reveal the top five mechanical upgrades that deliver measurable results and long-term ROI for today’s facilities.

1. Upgrade to High-Efficiency HVAC Systems

One of the largest energy consumers in any building is the heating, ventilation, and air conditioning (HVAC) system. Replacing outdated equipment with high-efficiency units—such as variable refrigerant flow (VRF) systems, modular chillers, or condensing boilers—can reduce energy use by 20–40%.

Modern HVAC systems integrate seamlessly with smart controls and respond dynamically to occupancy, weather, and indoor air quality. This combination not only lowers energy costs but also enhances occupant comfort.

Key Benefits

- Reduced energy consumption through advanced compressor modulation.

- Improved indoor air quality with demand-controlled ventilation.

- Lower maintenance costs via predictive diagnostics.

Pro Tip: Conduct a building energy audit before upgrading to determine optimal system sizing and ensure maximum efficiency gains.

2. Integrate Advanced Building Automation Systems (BAS)

The brains behind energy management lie in a well-designed Building Automation System (BAS). Modern BAS platforms use data-driven intelligence to monitor, control, and optimize all mechanical systems in real-time.

By integrating HVAC, lighting, and water systems into one centralized dashboard, facility managers can detect inefficiencies, adjust schedules, and even automate responses to occupancy patterns or temperature fluctuations.

Why It Matters

- Energy optimization through real-time analytics and adaptive algorithms.

- Remote monitoring enables instant alerts and control from mobile devices.

- Enhanced comfort by maintaining consistent thermal and lighting conditions.

Advanced BAS solutions often integrate with IoT-enabled sensors, delivering granular control that traditional systems simply cannot match.

Pro Insight: Retrofits using open-protocol BAS platforms (like BACnet or Modbus) allow you to modernize older infrastructure without full system replacement.

3. Retrofit with Variable Frequency Drives (VFDs)

Variable Frequency Drives are among the most cost-effective upgrades for achieving energy savings. By controlling motor speeds in pumps, fans, and compressors, VFDs allow equipment to operate precisely at the required load rather than running at full power continuously.

Energy-Saving Potential

Installing VFDs on large air handling units, chilled water pumps, or cooling tower fans can deliver up to 50% energy savings, depending on system load profiles.

Additional Benefits

- Extended equipment lifespan due to reduced mechanical stress.

- Quieter operation for improved occupant experience.

- Lower peak demand charges, directly impacting utility bills.

Optimization Tip: Pair VFDs with smart sensors and BAS integration for automated speed control based on real-time feedback from pressure and temperature sensors.

4. Implement Demand-Controlled Ventilation (DCV)

Traditional ventilation systems often operate at fixed rates, wasting energy when spaces are unoccupied or underutilized. Demand-Controlled Ventilation (DCV) addresses this by adjusting outdoor air intake based on actual occupancy or CO₂ levels.

When combined with a modern BAS, DCV systems significantly reduce heating and cooling loads by delivering the right amount of air only when needed.

Benefits of DCV

- Improved energy efficiency through reduced fan and conditioning loads.

- Enhanced indoor air quality based on real-time occupancy.

- Compliance with ASHRAE standards for ventilation effectiveness.

DCV is especially effective in schools, offices, gyms, and conference centers, where occupancy fluctuates throughout the day.

Technical Insight: Pairing CO₂ sensors with VAV (Variable Air Volume) systems amplifies the efficiency of DCV retrofits.

5. Optimize Hydronic and Steam Systems

A well-tuned hydronic or steam distribution system can be the difference between mediocre and exceptional energy performance. Retrofitting with smart valves, pumps, and insulation upgrades can yield major efficiency gains.

Key Upgrade Areas

- Condensate recovery systems: Capture and reuse condensate to preheat feedwater.

- High-efficiency pumps: Replace constant-speed units with VFD-controlled pumps.

- Pipe insulation: Reduces heat loss and improves thermal stability.

These upgrades reduce thermal waste, enhance system responsiveness, and decrease boiler cycling, which translates directly into lower utility costs.

Optimization Strategy: Incorporate real-time flow monitoring and automated balancing valves to continuously fine-tune system performance.

Bonus: Leverage Data Analytics for Continuous Optimization

Energy efficiency doesn’t end with upgrades — it’s sustained through data-driven performance analytics. Modern facility management platforms provide continuous commissioning (Cx) and fault detection diagnostics (FDD) to ensure systems remain optimized over time.

By analyzing trends, predicting maintenance needs, and flagging anomalies before they escalate, analytics-driven insights can maintain optimal performance and prolong asset lifespan.

Ongoing Benefits

- 10–20% sustained energy savings post-retrofit.

- Proactive maintenance reduces unexpected downtime.

- Granular insights into performance trends and occupant comfort.

Action Point: Make analytics part of your facility’s ongoing energy management strategy, not just a one-time improvement effort.

The Business Case for Modernization

Investing in mechanical system upgrades isn’t just about sustainability — it’s about financial resilience and operational excellence. The ROI from these retrofits typically manifests within 2–5 years, through reduced energy costs, lower maintenance, and enhanced asset value.

Facility managers who adopt a phased upgrade strategy can spread out capital expenses while steadily improving performance. Moreover, many governments and utilities offer incentives and rebates for energy-efficient retrofits, further enhancing payback potential.

Final Thoughts

For facility managers aiming to reduce energy waste, improve comfort, and future-proof their assets, the path forward is clear: optimize, automate, and upgrade strategically.

By focusing on high-impact areas such as HVAC modernization, automation controls, VFD integration, demand-based ventilation, and hydronic optimization, you can unlock substantial savings while positioning your facility as a model of operational efficiency.

When executed systematically, these upgrades can transform buildings into intelligent, sustainable environments that align with both financial goals and environmental responsibility.